For nearly two decades, G Systems has designed and developed a wide variety of test systems for several divisions across Lockheed Martin. From our first project upgrading the legacy F-35 flight test instrumentation verification and calibration system, to much larger projects, including developing several systems for testing various features of the F-35, quickly creating three test systems for the Orion spacecraft, and helping perform a multi-million-dollar upgrade to the U.S. Navy’s MK 41 vertical launching system (VLS), G Systems has consistently designed, developed, and delivered high-quality automated test systems for Lockheed Martin.

As we look to the future, we know we are well positioned to help even more Lockheed Martin divisions meet their automated testing needs quickly and cost effectively.

Deep Understanding of Varying Needs Throughout the Organization

When developing any automated test solution – particularly in the aerospace and defense industry – we know there is a delicate balance between the needs of management and the needs of the technical staff performing the day-to-day operations.

Top priorities for management typically include risk mitigation, minimizing costs, and developing easy-to-maintain systems using commercial off-the-shelf (COTS) hardware rather than building proprietary systems. The staff using these systems daily typically wants a modern system that eliminates archaic equipment; a balance between using hardware and software that is so new that it is full of bugs but also not so mature that it risks obsolescence; and proper and thorough documentation. At G Systems, we deliver the best of both worlds.

Based on our nearly two decades of experience working throughout Lockheed Martin, we fully understand how to develop automated test systems that will be highly functional and meet the needs of the technical staff while balancing the business requirements of management.

A Relationship Built on Expertise and Experience

At G Systems, we offer broad engineering capabilities as well as decades of experience designing and building test systems for highly regulated industries. Our staff includes electrical and mechanical engineers as well as physicists, which means we have the expertise to solve a multitude of tough problems. We also have extensive knowledge in Department of Defense and Federal Acquisition Regulation (FAR) requirements, including ITAR-compliance, and have experience working on government projects.

Additionally, we’ve been through the rigorous process to become a Lockheed Martin supplier. We are already an approved vendor and can develop test systems quickly – both critical components when tight development time frames exist. We are also a National Instruments Gold Alliance Partner, which means we receive faster support that further accelerates our development times and enables us to provide better support to our end users as well.

A Proven Track Record of Success Throughout Lockheed Martin

Throughout the years, we have formed solid working relationships with numerous Lockheed Martin engineers, many of whom have moved into management and leadership positions. Because of the high-quality systems we have provided, our ability to reduce risk, and our reasonable pricing, our relationship with many of these engineers has continued to grow even as their positions and focus areas have changed.

While we’ve built and iterated on more than two dozen systems across various divisions of Lockheed Martin, to show the breadth of capabilities and domain expertise, highlights of just a few are included below.

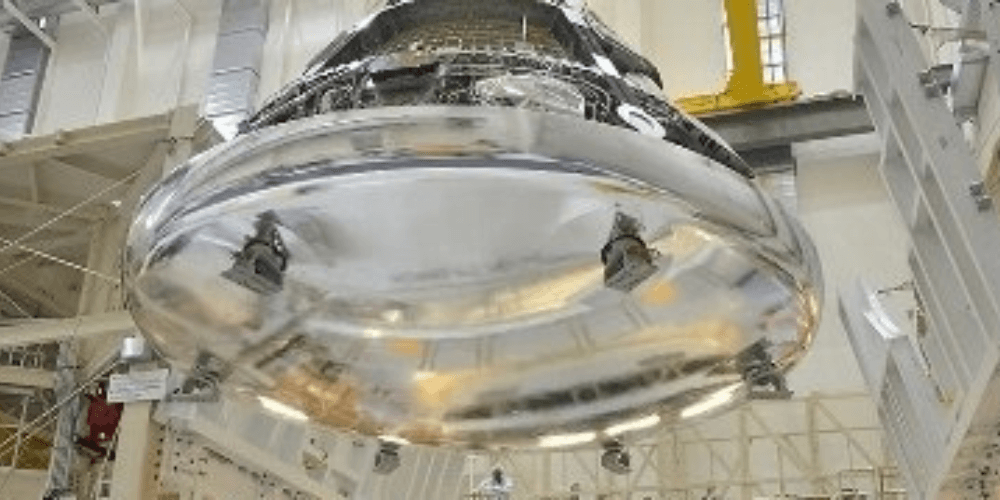

Orion Space Exploration Vehicle Test Station

We used concurrent development to build a comprehensive three-part test system that enables NASA to simulate and measure the effects the Orion spacecraft will experience during take-off, space flight, and re-entry. All three parts were developed in less than nine months.

F-35 Vehicle Systems Integration Facility Data Acquisition System

We developed highly flexible software and used COTS hardware to create a high-channel-count system consisting of five PXI chassis populated with a variety of NI DAQ boards for a total of 640 analog channels and 480 digital channels. After more than 15 years running the data acquisition system 24/7, the system is still reliably functioning.

U.S. Navy’s MK 41 Vertical Launching System

This VLS test system upgrade included the system design as well as development of custom test hardware, test interface connections, system self-test, and a test software environment for the VLS launcher module and launch sequencer. We developed the system in less time and for lower costs than could be done internally.

Mil-1394b Nine-Channel Repeater Assemblies

The nine-channel repeater box is used on the flight line to regenerate and amplify Mil-1394b communication signals transmitted between the MATRIX tester and the test ports on the F-35 aircraft. We delivered 12 repeater assemblies.

NLOS-LS Container Launch Unit Common Core Test System

We developed two automated test systems for Lockheed Martin Missiles & Fire Control to validate the subsystems of a missile launcher. The test platform provides a wide array of instrumentation for complete coverage of test program sets in a single test system.

Portable Digital Data Acquisition System for Engine Inlet Testing

We designed and developed a fully portable wind tunnel data acquisition system with 128+ channels of simultaneously sampled dynamic pressure measurements on a PXI chassis. The new system significantly increased capabilities, and we delivered it in less than 20 weeks for approximately the same cost to simply upgrade and integrate the signal conditioning subsystems on the original system.

Fostering Our Relationship for the Future

As existing test systems age and require upgrading at the same time new projects emerge, it is important to have an established relationship with a third-party expert that is familiar with your organization and can help alleviate workloads as necessary.

We are brought back in by Lockheed Martin time and time again to upgrade and migrate systems we initially created. Because of our engineering team’s long tenure, this often means that the same people who created the original system are the ones updating that same system.

As a result of our nearly two decades of experience working on numerous new and existing Lockheed Martin systems, we are well positioned to continue to help drive success and manage risk for any division or team within the organization. From developing new test and measurements systems to upgrading and retrofitting existing equipment, we always welcome the opportunity to assist Lockheed Martin.