Design and build an automated, single-rack, common core test system with interchangeable test fixtures for current and future products using National Instruments PXI modular instruments and Virginia Panel mass interconnect solutions.

Figure 1: Production ATE System

Introduction

A manufacturer of GPS tracking modules needed an automated test stand to perform functional test and device programming for their overseas manufacturing operation in China. G Systems

developed a system that programs the devices, simulates real GPS satellite signals (over-the-air), and performs mixed-signal and RF measurements. All test modules were developed in LabVIEW™ and test sequencing and data management was provided by TestStand™. NI Switch Executive was used to control all power and RF switching functions through TestStand sequence steps.

Common Core Test Hardware

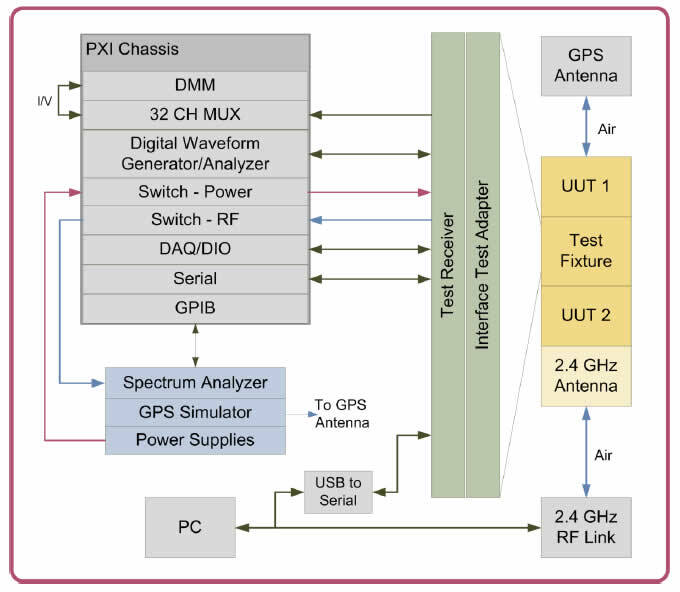

The following figure shows the overall hardware design and PXI instrumentation used in the common core production test system (reference Figure 2).

Figure 2: RF and GPS Common Core ATE Design

The units under test (UUT) required serial communication for device setup and configuration, which was either direct serial over PXI-8420/4 or via 2.4 GHz USB serial communications device (final test over-the-air interface).

Digital and analog IO were achieved using PXI-6541 high-speed DIO (for any pattern generation needs) and PXI-6221 (static control lines and fixture relay control). A PXI-4070 DMM was used for a majority of voltage and current tests through a PXI-2527 multiplexer. Some fixture relay design was needed to accommodate switching the DMM for power-on and sleep current tests (routed through power supply) as well as regular voltage tests.

Rack instruments were controlled using PXI-GPIB including Agilent DC power supplies, a spectrum analyzer, and a GPS simulator.

Each test adapter is capable of testing two modules either in series or parallel, which meant all tester resources had to be designed with parallelism in mind (duplicate and/or dedicated connections).

Production ATE Automation Software

National Instruments LabVIEW was used for all instrumentation control and encapsulated tests which enabled efficient and hierarchical programming from the TestStand sequence development environment. With a modular approach to software design, some tests could be implemented with a simple series of LabVIEW instrumentation driver calls whereas more intensive tests or analysis could be pushed to higher level LabVIEW modules.

NI Switch Executive proved to be a useful tool for designing the switch software. All switch connections and switch groups (routes) were defined and documented in Switch Executive for easy calling from within the TestStand sequence. Switch route connect/disconnect was handled at each test step using the built-in TestStand switching capabilities (test step properties tab). Using Switch Executive eliminated the need for developing custom switch management software and a more robust switch definition mechanism for testing and documentation.

The high level of integration between TestStand and LabVIEW allowed for a clean software architecture design with easily modified test parameters, limits, switching, and data reporting. All aspects of the production testing were automated with minimal user interaction which helps to speed production throughput and minimize testing errors.